-

Table of Contents

- Introduction

- How 5G is Revolutionizing Industrial Automation and Robotics

- The Benefits of 5G for Industrial Automation and Robotics

- The Challenges of Implementing 5G in Industrial Automation and Robotics

- The Future of Industrial Automation and Robotics with 5G

- The Impact of 5G on Industrial Automation and Robotics Security

- Conclusion

“Unlock the Future of Industrial Automation with 5G Technology!”

Introduction

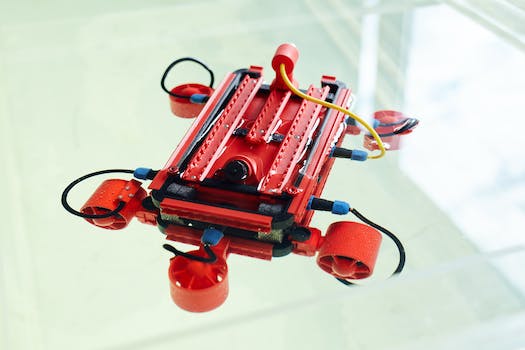

The fifth generation of mobile networks, 5G, is set to revolutionize the way we interact with technology. 5G promises to bring faster speeds, lower latency, and more reliable connections than ever before. This will have a huge impact on industrial automation and robotics, as 5G will enable machines to communicate with each other in real-time, allowing for more efficient and accurate operations. 5G will also enable the development of new technologies such as autonomous robots and drones, which can be used to automate processes and reduce costs. In this article, we will explore the potential impact of 5G on industrial automation and robotics, and how it can be used to improve efficiency and productivity.

How 5G is Revolutionizing Industrial Automation and Robotics

The introduction of 5G technology is revolutionizing the industrial automation and robotics industry. 5G is a fifth-generation cellular network technology that offers faster speeds, lower latency, and more reliable connections than previous generations of cellular networks. This new technology is enabling industrial automation and robotics to become more efficient, reliable, and cost-effective.

5G technology is allowing industrial automation and robotics to become more connected than ever before. With 5G, industrial robots can communicate with each other and with other machines in real-time, allowing for faster and more accurate decision-making. This improved communication also allows for more efficient data collection and analysis, which can be used to optimize production processes.

5G technology is also enabling industrial automation and robotics to become more intelligent. With 5G, robots can be equipped with advanced sensors and AI-powered algorithms that allow them to make decisions and take actions autonomously. This improved intelligence allows robots to be more accurate and efficient in their tasks, resulting in improved productivity and cost savings.

5G technology is also making industrial automation and robotics more secure. With 5G, robots can be equipped with advanced security measures such as encryption and authentication protocols that protect them from cyberattacks. This improved security helps to ensure that robots are not vulnerable to malicious actors and that data is kept safe and secure.

Finally, 5G technology is making industrial automation and robotics more accessible. With 5G, robots can be deployed in remote locations, allowing companies to expand their operations into new markets. This improved accessibility also allows companies to reduce their operational costs, as they no longer need to invest in expensive infrastructure to deploy robots in remote locations.

In conclusion, 5G technology is revolutionizing the industrial automation and robotics industry. This new technology is enabling robots to become more connected, intelligent, secure, and accessible, resulting in improved efficiency, productivity, and cost savings. As 5G technology continues to evolve, we can expect to see even more advancements in the industrial automation and robotics industry.

The Benefits of 5G for Industrial Automation and Robotics

The fifth generation of cellular technology, 5G, is set to revolutionize the industrial automation and robotics industry. 5G offers a range of benefits that will enable industrial automation and robotics to become more efficient, reliable, and cost-effective.

One of the main benefits of 5G is its high speed and low latency. 5G networks are capable of speeds up to 10 gigabits per second, which is significantly faster than the current 4G networks. This increased speed will allow for faster data transfer and communication between machines, enabling industrial automation and robotics to operate more quickly and efficiently. Additionally, 5G networks have a latency of less than one millisecond, which is much lower than 4G networks. This low latency will enable industrial automation and robotics to respond to commands and instructions in real-time, allowing for faster and more accurate operations.

Another benefit of 5G is its increased capacity. 5G networks are capable of handling more devices than 4G networks, which will enable industrial automation and robotics to operate more effectively. This increased capacity will also allow for more data to be transferred between machines, enabling more complex operations and tasks to be completed.

Finally, 5G networks are more secure than 4G networks. 5G networks use advanced encryption and authentication protocols to ensure that data is secure and protected from unauthorized access. This increased security will help to protect industrial automation and robotics from cyber-attacks and other malicious activities.

Overall, 5G offers a range of benefits that will enable industrial automation and robotics to become more efficient, reliable, and cost-effective. With its increased speed, low latency, increased capacity, and improved security, 5G is set to revolutionize the industrial automation and robotics industry.

The Challenges of Implementing 5G in Industrial Automation and Robotics

The introduction of 5G technology into industrial automation and robotics is a major step forward in the development of these industries. 5G promises to bring faster speeds, lower latency, and more reliable connections to the industrial automation and robotics sector. However, the implementation of 5G technology in these industries is not without its challenges. In this blog, we will discuss the challenges of implementing 5G in industrial automation and robotics.

One of the biggest challenges of implementing 5G in industrial automation and robotics is the cost. 5G technology is expensive to implement and maintain, and the cost of upgrading existing infrastructure to support 5G can be prohibitively high. Additionally, the cost of 5G-enabled devices and components can be expensive, making it difficult for companies to invest in the technology.

Another challenge of implementing 5G in industrial automation and robotics is the complexity of the technology. 5G technology is complex and requires a high level of technical expertise to implement and maintain. This can be a challenge for companies that do not have the necessary resources or expertise to manage the technology.

Finally, there are security concerns associated with 5G technology. 5G networks are more vulnerable to cyberattacks than traditional networks, and companies must ensure that their networks are secure and protected from potential threats. Additionally, companies must ensure that their 5G networks are compliant with industry regulations and standards.

In conclusion, the implementation of 5G in industrial automation and robotics is a major step forward in the development of these industries. However, the implementation of 5G technology is not without its challenges. Companies must consider the cost, complexity, and security concerns associated with 5G technology before investing in the technology.

The Future of Industrial Automation and Robotics with 5G

The advent of 5G technology is set to revolutionize the industrial automation and robotics industry. 5G is the fifth generation of cellular network technology, and it promises to bring faster speeds, lower latency, and more reliable connections than ever before. This will enable industrial automation and robotics to become more efficient, reliable, and cost-effective.

5G technology will enable industrial automation and robotics to operate at a much faster rate than ever before. This will allow for faster data processing, which will enable robots to make decisions and take action more quickly. This will also allow for more complex tasks to be completed in a shorter amount of time. Additionally, 5G will enable robots to communicate with each other more quickly and reliably, allowing for better coordination and collaboration between robots.

5G will also reduce latency, which is the time it takes for a signal to travel from one point to another. This will enable robots to respond to commands more quickly and accurately. This will also allow for more complex tasks to be completed in a shorter amount of time.

Finally, 5G will provide more reliable connections than ever before. This will enable robots to stay connected to the network even in areas with poor signal strength. This will ensure that robots are able to stay connected and continue to operate even in challenging environments.

Overall, 5G technology is set to revolutionize the industrial automation and robotics industry. It will enable robots to operate faster, more reliably, and more cost-effectively than ever before. This will open up a world of possibilities for industrial automation and robotics, and it will help to make the industry more efficient and productive.

The Impact of 5G on Industrial Automation and Robotics Security

The introduction of 5G technology is set to revolutionize the way industrial automation and robotics are used in the modern world. 5G is a new wireless technology that promises faster speeds, lower latency, and more reliable connections than ever before. This will have a major impact on the security of industrial automation and robotics systems, as 5G will enable more secure and reliable communication between machines and devices.

The increased speed and reliability of 5G will allow for more efficient and secure communication between machines and devices. This will enable industrial automation and robotics systems to be more responsive and reliable, as well as more secure. 5G will also enable more secure data transmission, as it will be able to encrypt data more effectively than current technologies. This will help to protect sensitive data from malicious actors, as well as reduce the risk of data breaches.

5G will also enable more secure remote access to industrial automation and robotics systems. This will allow for remote monitoring and control of these systems, as well as the ability to update and patch them remotely. This will help to reduce the risk of malicious actors gaining access to these systems, as well as reduce the risk of data breaches.

Finally, 5G will enable more secure communication between machines and devices. This will help to reduce the risk of malicious actors gaining access to these systems, as well as reduce the risk of data breaches. 5G will also enable more secure data transmission, as it will be able to encrypt data more effectively than current technologies.

Overall, the introduction of 5G technology will have a major impact on the security of industrial automation and robotics systems. 5G will enable more secure and reliable communication between machines and devices, as well as more secure remote access and data transmission. This will help to reduce the risk of malicious actors gaining access to these systems, as well as reduce the risk of data breaches.

Conclusion

In conclusion, 5G technology has the potential to revolutionize industrial automation and robotics. It can provide faster, more reliable, and more secure communication between machines and devices, enabling more efficient and cost-effective operations. 5G can also enable the development of new applications and services, such as remote monitoring and control, that can further improve the efficiency and productivity of industrial automation and robotics. As 5G technology continues to evolve, it will become increasingly important for industrial automation and robotics to take advantage of its capabilities.